Portfolio

PLANT CONSTRUCTION

We offer complete solutions – you can rely on us.

To meet the challenges of modern industry, we employ highly qualified engineers, developers and specialists. From design, material procurement and production to assembly and commissioning, we support every phase of your project.

Our range of services includes:

- Project planning & management

- Creation of functional specifications, development of concepts

- 3D design

- Production drawings

- Load analysis based on FE calculation

- Production, assembly and commissioning

- Non-destructive testing

- Documentation

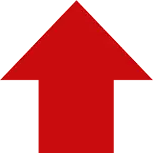

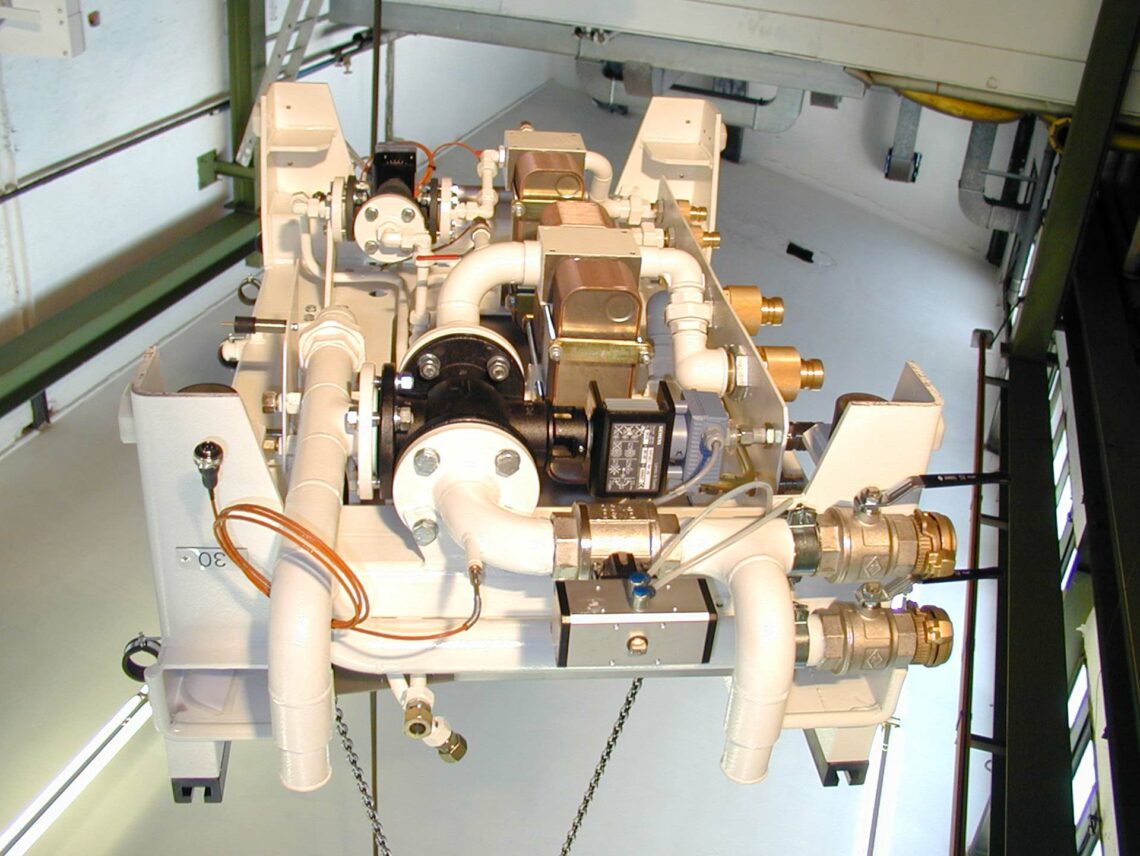

Stainless steel tank with dosing system

Test facility with insulation

Treatment plant for brine

INDUSTRIAL BURNERS

We’re fired up for our projects

Sophisticated partial and complete solutions in the field of industrial furnaces are our passion – we support renowned industrial customers in Austria and throughout the world.

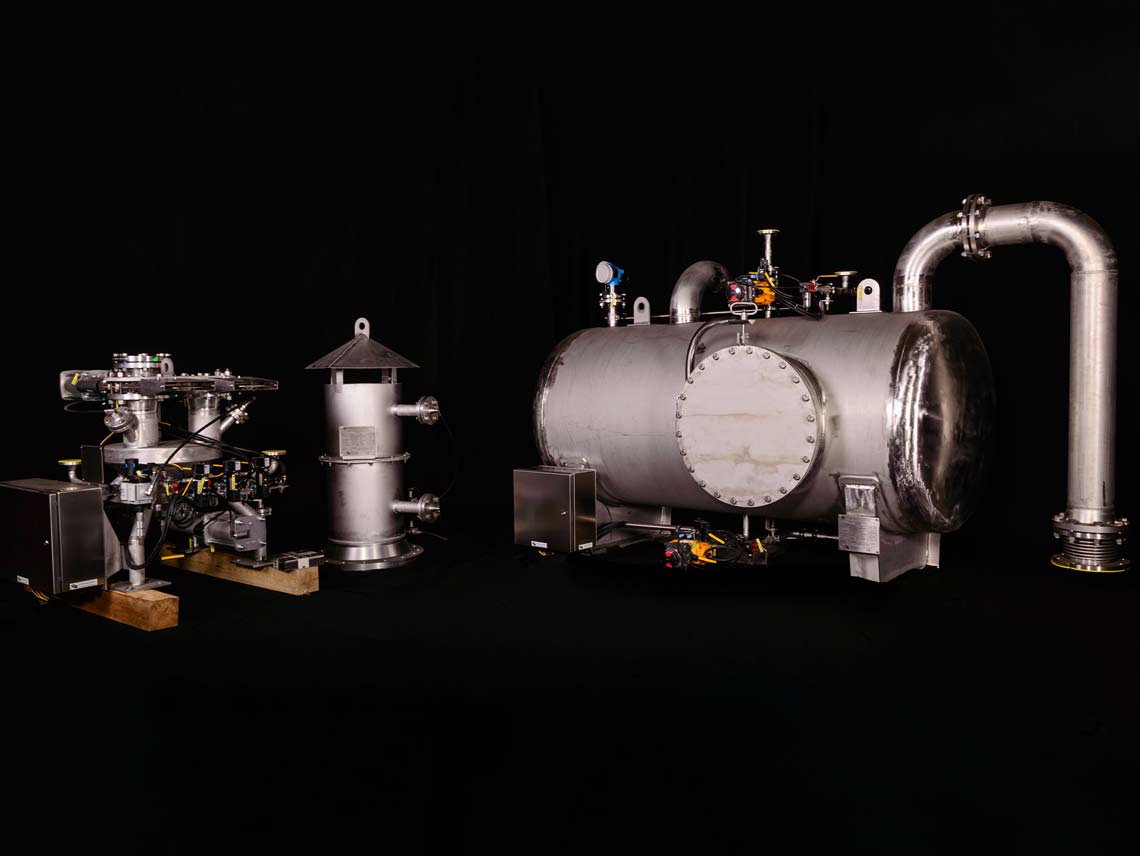

Our in-depth expertise in the construction of burners for thermal processing plants extends across all industrial sectors: we manufacture our own models, but also produce burner models for our long-standing partners and customers.

We offer efficient combustion solutions for gaseous, liquid or solid fuels in combination with air or oxygen – with our output range extending from a few kW to over 200 MW.

Our range of experience includes:

- Burner construction for thermal processing plants in all industrial sectors (e.g. steel and non-ferrous metal industry, glass and cement industry, chemical industry, waste incineration and recycling, heat generation, and more)

- Natural gas/oxygen burners

- Rotary kiln burners

- Boiler burners

- Special burners

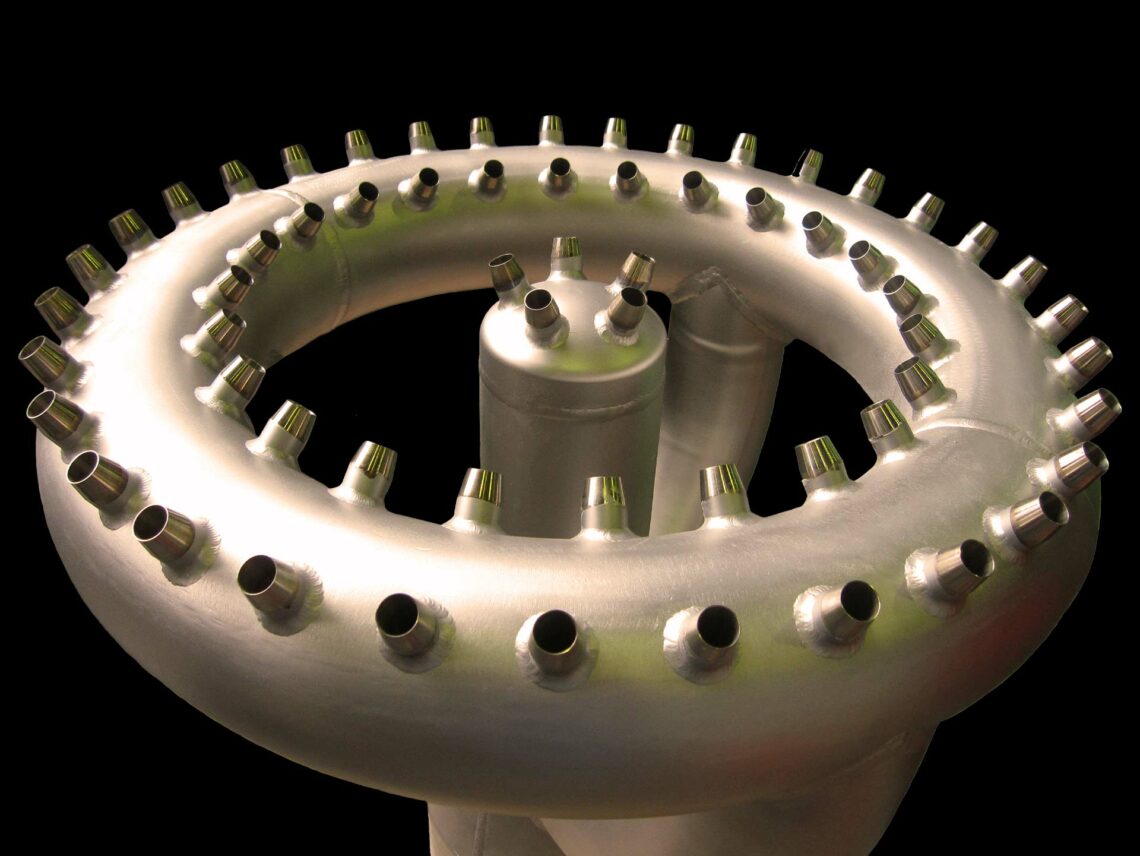

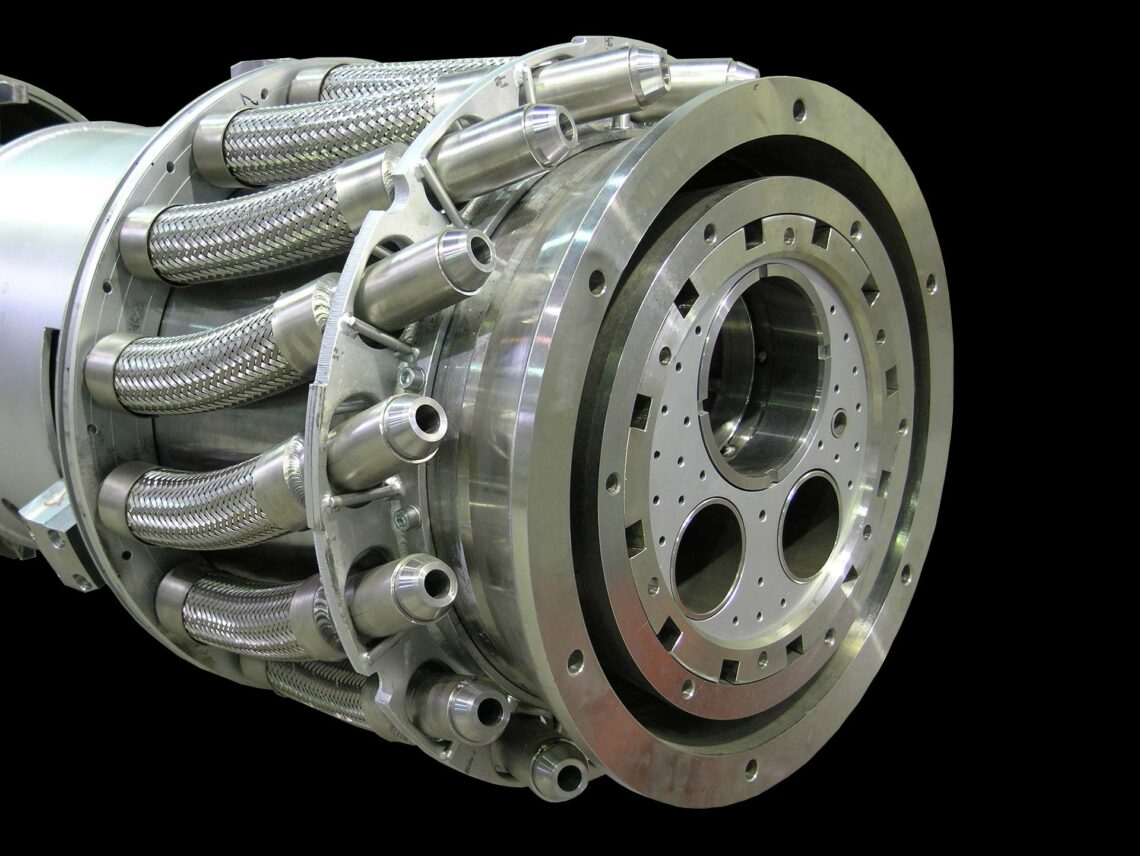

Rotary kiln burners

Oxy-fuel burners

Industrial burners for special fuels

Industrial burners for special fuels

Industrial burners for special fuels

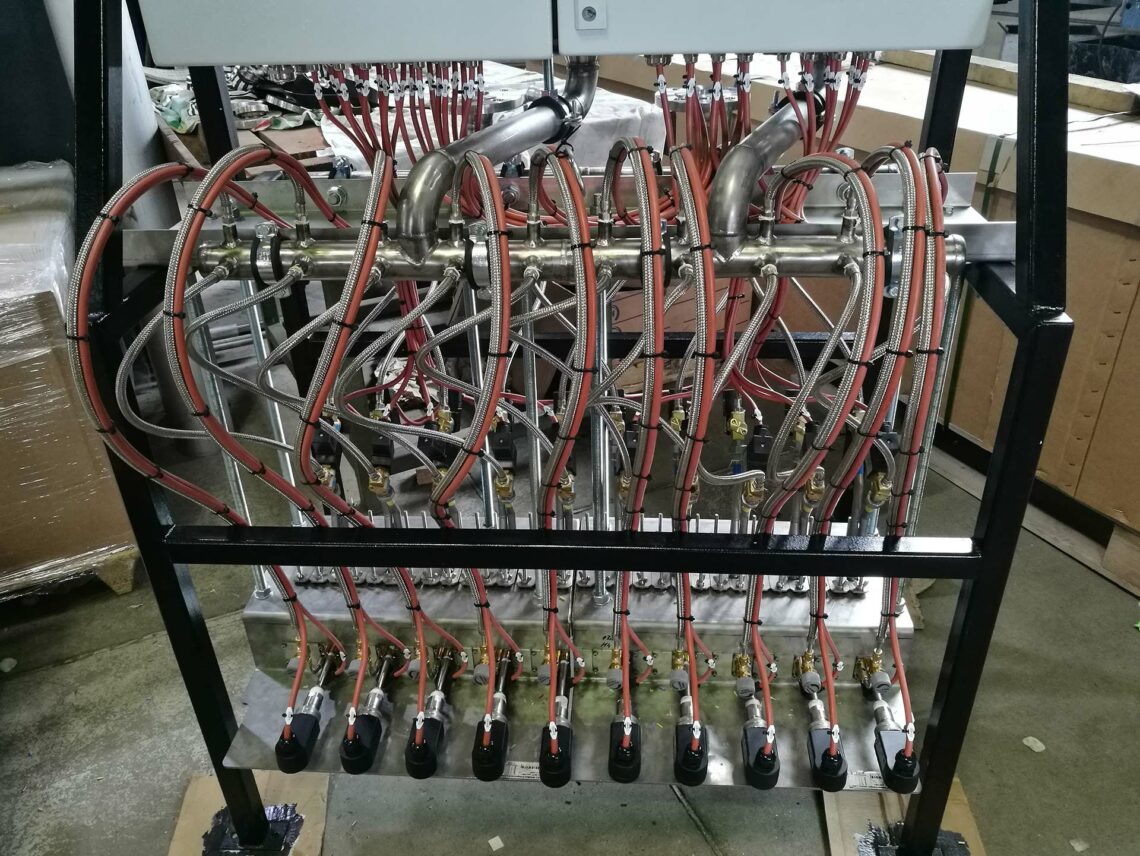

VALVE RACK

We deliver measurable precision

Our range of experience includes:

- O2 control systems

- Heavy fuel oil control systems

- H2 control systems

- NG/O2 combination

- H2/NG/O2 combination

- Oil/NG/O2 combination

Our range of services includes:

- Project planning & management

- 3D design

- Production drawings

- Production & assembly

- Non-destructive testing

-

Documentation according to AD 2000, EN 13445 or

EN 13480

Valve station for natural gas and flue gas

Stainless steel valve station

Air distributor

PRESSURE EQUIPMENT

We can withstand any pressure

With the support of our comprehensive quality management system, we manufacture pressure equipment and pipework in accordance with the highest standards of the Pressure Equipment Directive 2014/68/EU. From dimensioning to design, production, testing and documentation, we follow the strict specifications of AD 2000, EN 13445 and EN 13490. With our passion and expertise, we are committed to ensuring that our pressure equipment and pipework not only comply with European standards and requirements, but also exceed the high expectations of our customers.

Our range of experience includes:

- Storage tanks (ammonia tank, oil, compressed air, etc.)

- Pressure vessels (compressed air, H2O, H2SO4, oil, diesel, etc.)

Our range of services includes:

- Project planning & management

- Creation of functional specifications, development of concepts

- 3D design

- Production drawings

- Production, assembly and commissioning based on the Pressure Equipment Directive 2014/68/EU

- Non-destructive testing

- Documentation according to AD 2000, EN 13445 or EN 13480

Hydraulic tanks for drilling equipment

Combustion chambers

Storage tank with special coating

Storage tanks with special coating

PROTOTYPE PRODUCTION

We are always willing to step out of our comfort zone

We love challenges and are not afraid to develop innovative processes and products.

The ideas and creativity of our employees are the essence of our success. Together, we have laid an impressive foundation in the field of testing facilities and demonstration plants. This is not only a sign of our expertise, but also an expression of our tireless pursuit of progress.

Simply put, we are always willing to step out of our comfort zone and are excited to break new ground.

A selection of our innovative projects:

- Recophos

- FP 7 Europe project

- Development of a process and production of a plant for the recovery of phosphorus from sewage sludge ash.

- Project management: Montanuniversität Leoben, Chair of Thermal Processing Technology

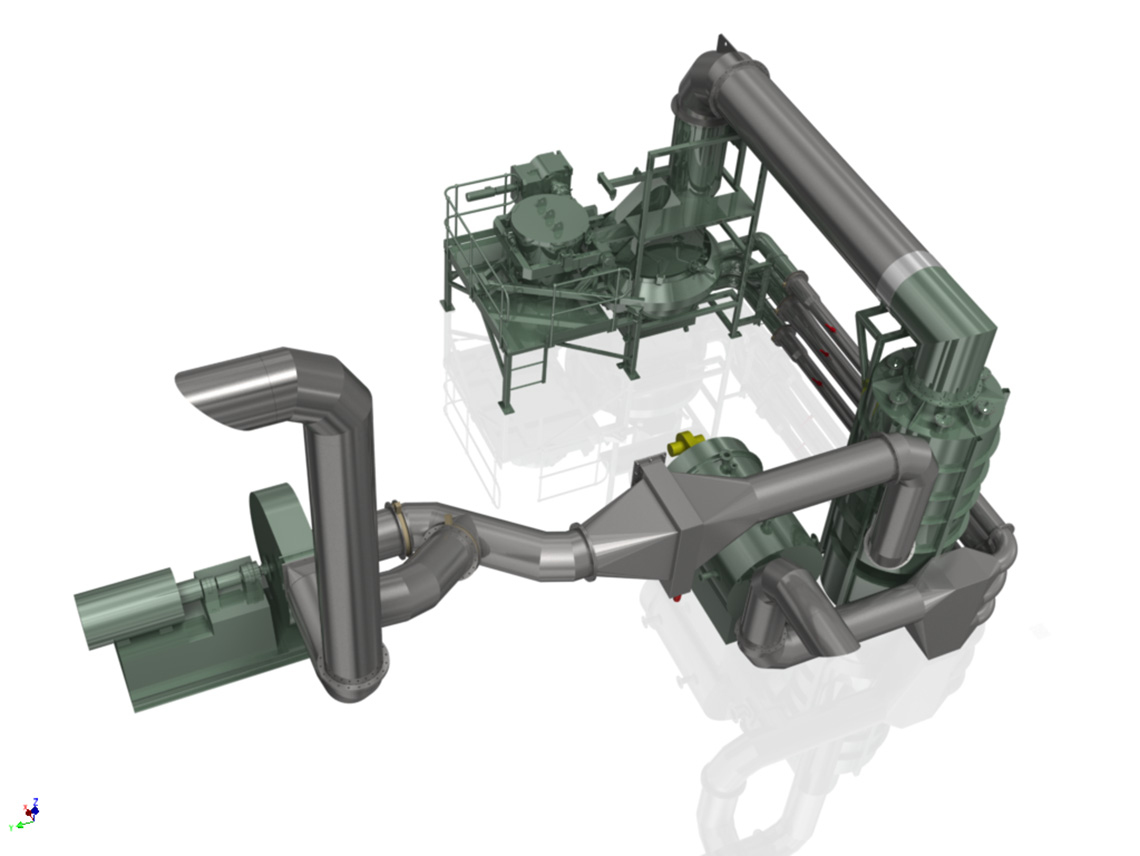

- Dry slag granulation

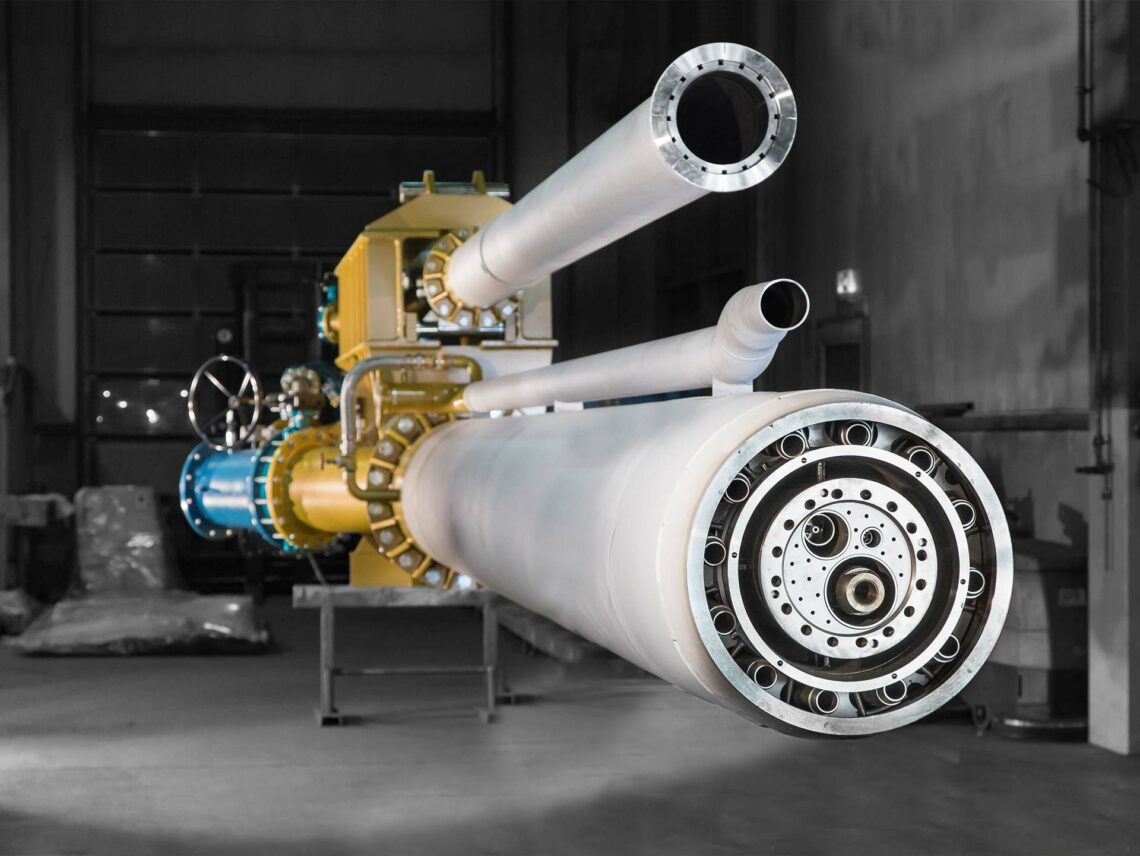

- Test facility for the dry granulation of blast furnace slag with combined heat recovery

- Montanuniversität Leoben, Chair of Thermal Processing Engineering

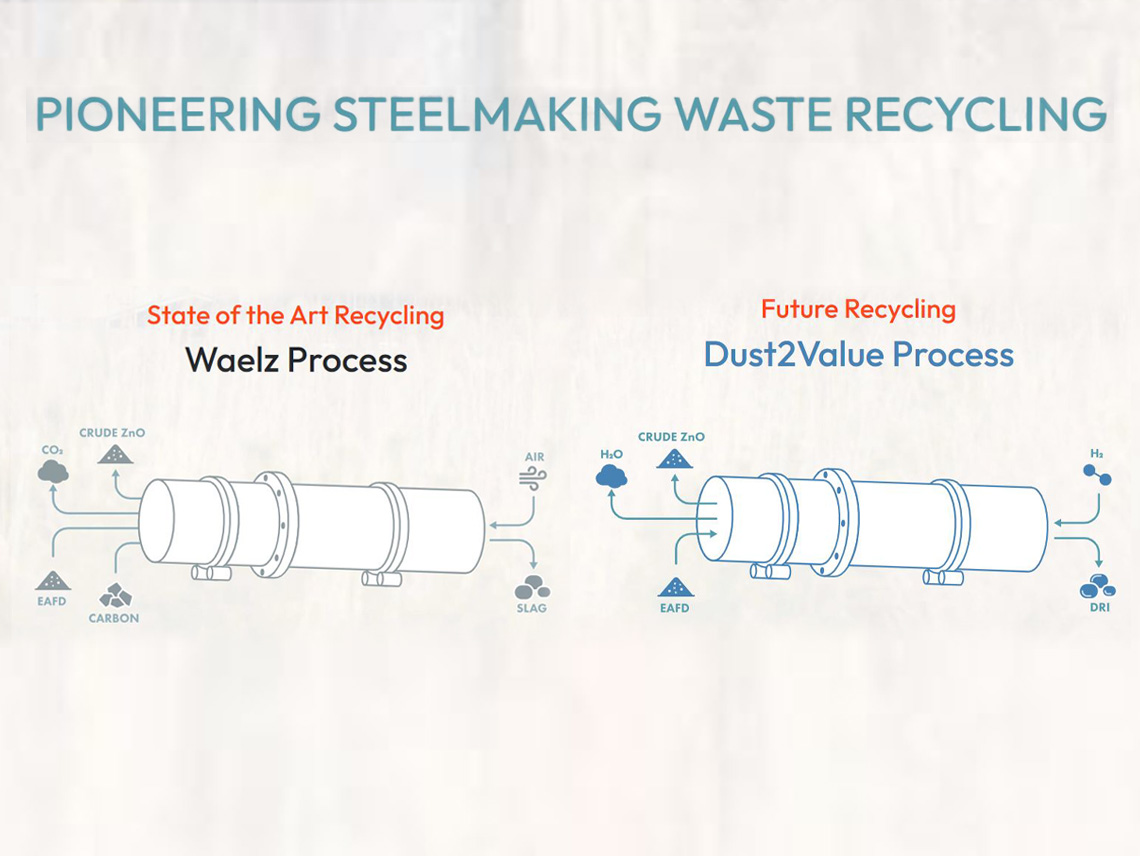

- Dust2Value

- Horizon Europe project

- Development of a process and construction of a demonstration plant for the recovery and recycling of waste streams from the steel industry using hydrogen

- Montanuniversität Leoben, Chair of Nonferrous Metallurgy

- Natural gas/air burner for the production of glass beads from glass granulate

- Cooperation with SWARCO

- Development & production of 2 MW natural gas/air burners

Recophos demonstration plant

Dry slag granulation

Dry slag granulation

Dust2Value process

Natural gas/air burner

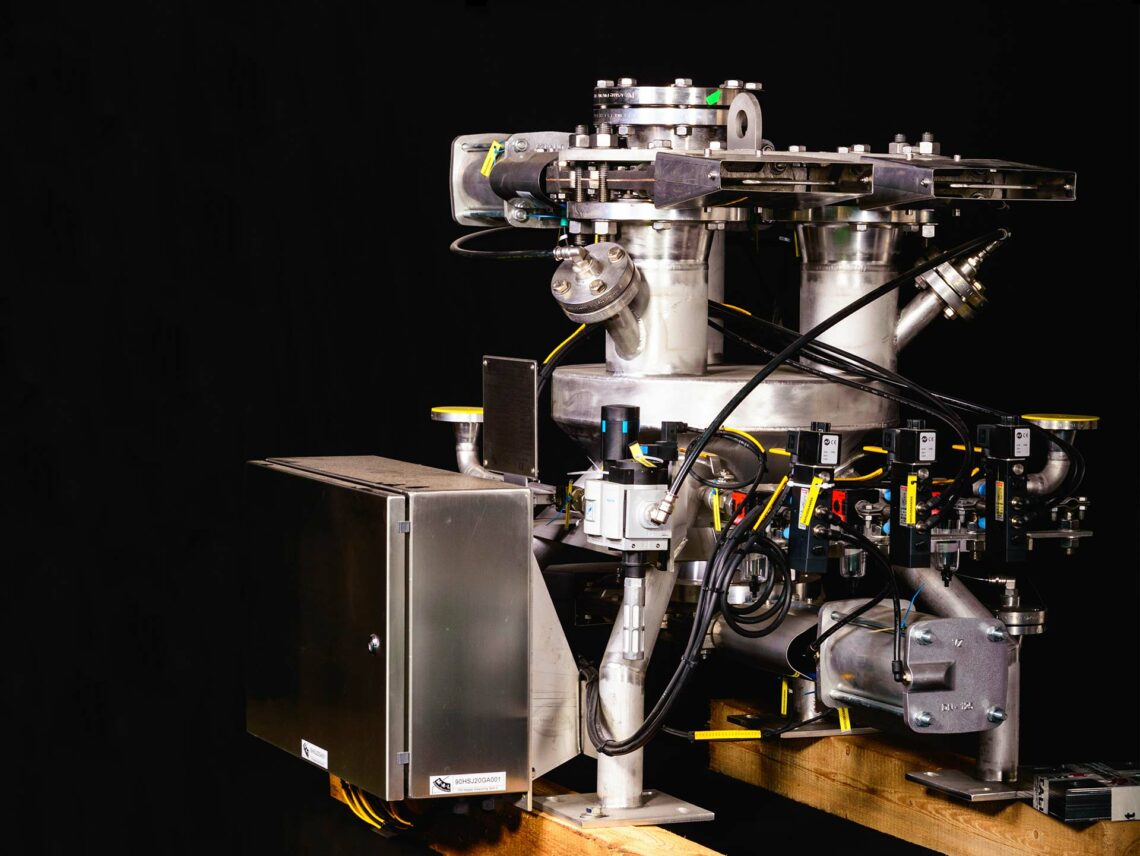

Gas injection

Oxy-fuel burner for melting steel mill dust

SPECIAL-PURPOSE MACHINERY

We think in terms of solutions

In a constantly evolving world, customised solutions are the key to success.

We support our customers from the first sketch to the final implementation. Our experienced designers and engineers work hand in hand with our partners to understand the requirements and develop innovative concepts.

Our machines stand for maximum precision and quality. Thanks to state-of-the-art production technologies and strict quality controls, we ensure that every solution that leaves our plant meets the highest standards. We don’t just build – we create with passion.

Our range of experience includes:

- Cooling systems for an EAF plant

- Engine test bench

- High-current busbars

- Copper mould for ESR plant

- Swirler

Our range of services includes:

- Project planning, costing & management

- 3D design

- Production drawings

- Production & assembly

- Non-destructive testing

- Documentation

Melting pot for ESR plant

MAS burner head

Oxy-fuel burner

for selective hardening of steel profiles

Panel saw for insulating materials

Dosing system

Test stand

STEEL CONSTRUCTION / SHEET METAL TECHNOLOGY

We are strong in every detail

We are convinced that every project, no matter how big or small, has the potential to shape the future. That is why we are committed to developing customised solutions that not only meet current requirements, but also rise to future challenges.

Thanks to our many years of experience, we can offer a comprehensive range of services – from planning and design to the implementation of complex projects.

As a specialist company certified in accordance with EN 1090-2 – EXC3, we guarantee the highest standards in the design and quality of our products.

Our range of experience includes:

- Platforms

- Burner carriages

- Frames

- Various steel construction components for industrial partners

Our range of services includes:

- Creation of functional specifications, development of concepts

- Production drawings

- Layout & design

- 3D design

- Non-destructive testing

Panel saw

Steriliser

Wiener Prater assault boat

INDUSTRIAL SERVICE

We take service to the next level

We believe that service should be more than just responding to enquiries. We offer comprehensive service and optimisation concepts for industrial plants of all kinds.

Our comprehensive services range from preventative maintenance and inspection services to precise functional tests and statutory inspections to ensure that every plant runs smoothly. Our aim is not simply to solve problems, but to proactively plan for the future.

But we even go one step further! In times when spare parts are scarce or no longer manufactured, we refuse to be discouraged. Instead, we put our innovative spirit and expertise to work and produce customised solutions.

Our range of services includes:

- Comprehensive servicing & optimisation of industrial plants

- Technical inspections of industrial plants

- Functional tests

- Safety inspections

- Statutory inspections in accordance with the Austrian Gas and Water Association (ÖVGW)

- Pipework

- Spare parts supply

- Production of special spare parts